Industrial machinery and equipment are subject to wear and tear, which can have a significant impact on productivity and profitability. Grinding mills, in particular, play a crucial role in various industries such as mining, quarrying, cement, and metal recycling, where the efficient comminution of materials is essential for downstream processes.

At Qiming Casting, we recognize the critical importance of wear-resistant components in optimizing the performance and longevity of grinding mills. That’s why we are proud to introduce our revolutionary Cr-Mo Alloy Mill Liners, which are reshaping industry standards and redefining expectations for durability and reliability.

Join us as we delve into how Qiming Casting’s Cr-Mo Alloy Mill Liners are spearheading a new era of excellence in the field of wear-resistant materials.

Understand About Qiming Casting Cr-Mo Alloy Mill Liners

Our Cr-Mo Alloy Mill Liners offer many benefits over traditional manganese steel liners, including superior wear resistance, longer service life, and reduced maintenance costs. Below are some of the key features that make our Cr-Mo Alloy Mill Liners stand out in the market:

Experience and Expertise

With more than 20 years of experience in the field, Qiming Casting has honed its expertise in producing Cr-Mo alloy mill liners. Our team of skilled professionals is dedicated to ensuring the highest standards of quality and precision in every aspect of the manufacturing process.

This extensive experience enables us to understand the unique requirements and challenges of industries such as AG, SAG, and Ball mills, allowing us to tailor our products to meet and exceed customer expectations.

This expertise, combined with our state-of-the-art facilities and advanced technology, has cemented Qiming Casting as a leading provider of Cr-Mo Alloy Mill Liners in the industry.

Superior Wear Characteristics

One of the key features of Qiming Casting’s Cr-Mo Alloy Mill Liners is their exceptional wear characteristics. Constructed from high-quality chrome moly steel, these liners offer unparalleled resistance to abrasion and wear, even in the most demanding operating conditions.

This longevity translates to reduced downtime and maintenance costs for our customers, ultimately leading to increased productivity and profitability. Also, our Cr-Mo Alloy Mill Liners exhibit excellent impact resistance, keeping your mill running efficiently in the face of high-impact grinding environments. This superior wear performance makes them an ideal choice for grinding mills operating in industries where abrasive materials are prevalent.

Impact Resistance

In addition to their superior wear resistance, our Cr-Mo Alloy Mill Liners also exhibit impressive impact resistance. This is particularly crucial in applications where the grinding process involves the crushing and pulverizing of hard and abrasive materials.

Our liners are engineered to withstand high-impact forces, ensuring uninterrupted operation and prolonged service life for grinding mills. This feature is especially significant in industries such as mining and quarrying, where downtime and equipment failure can result in significant financial losses.

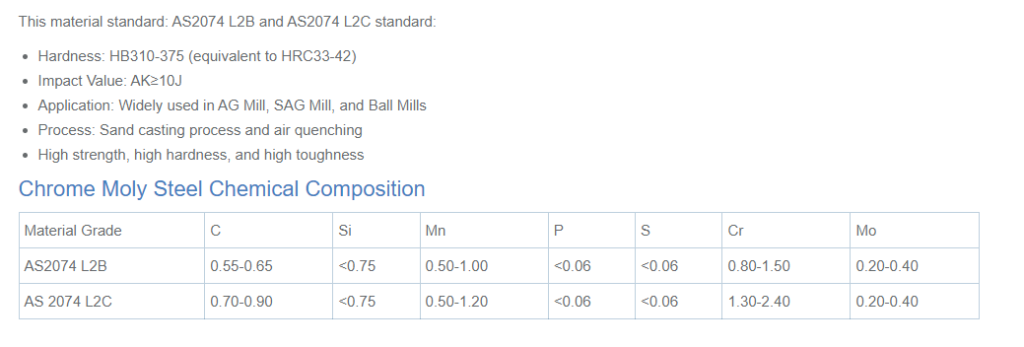

Material Standards and Composition

At Qiming Casting, we adhere to stringent material standards to guarantee the quality and performance of our products. Our Cr-Mo Alloy Mill Liners conform to AS2074 L2B and AS2074 L2C standards, with hardness levels ranging from HB310-375 (equivalent to HRC33-42) and an impact value of AK=10J.

The chemical composition of the chrome moly steel used in our liners is meticulously controlled to ensure optimal properties, including high chromium and molybdenum content for enhanced wear resistance and toughness. This attention to detail in material composition is what sets our Cr-Mo Alloy Mill Liners apart from the competition.

Product Range and Versatility

In addition to Cr-Mo Alloy Mill Liners, Qiming Casting offers a diverse range of wear-resistant products to cater to various industrial needs. Our extensive product lineup includes crusher wear parts, crusher spare parts, shredder wear parts, apron feeder pans, and electric rope shovel parts.

This comprehensive range reflects our commitment to providing holistic solutions to our customers’ wear-related challenges, ensuring maximum efficiency and reliability across their operations. With our versatile product range and unmatched expertise, Qiming Casting is your one-stop-shop for all your wear-resistant component needs.

Final Thoughts

Ultimately, Qiming Casting’s Cr-Mo Alloy Mill Liners represent a paradigm shift in industry standards for wear-resistant materials. With their superior wear characteristics, impact resistance, and adherence to stringent material standards, our mill liners offer unparalleled performance and durability in the most demanding applications.

Backed by over two decades of experience and expertise, we continue to push the boundaries of innovation to meet the evolving needs of our customers and revolutionize the industries we serve.

So why wait? Get in touch with us today and experience the difference our Cr-Mo Alloy Mill Liners can make for your operations. The future of wear-resistant materials starts here at Qiming Casting. Let us be your partner in success.